The Art of Screen Printing: Unveiling the Role of Mesh in Creating Vibrant and Crisp Prints

The Art of Screen Printing: Unveiling the Role of Mesh in Creating Vibrant and Crisp Prints

Mesh screen printing, also known as silk screening, is a versatile and popular method of printing that has been used for centuries to transfer designs onto various surfaces. From apparel and posters to signage and artwork, silk screen cloth offers a unique and vibrant way to bring designs to life. At the heart of this intricate process lies an essential element: mesh. The choice of mesh plays a crucial role in determining the quality, detail, and overall outcome of screen-printed designs. In this article, we will delve into the art of screen printing screens and explore the significance of mesh in creating vibrant and crisp prints.

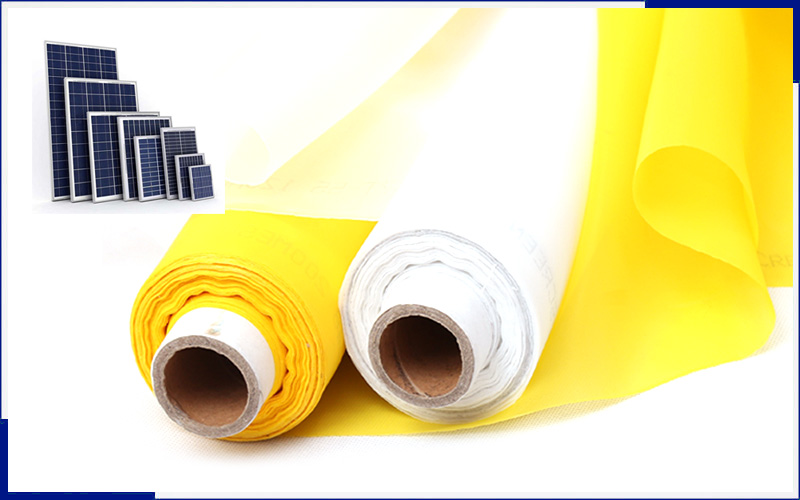

The process of screen printing mesh involves creating a stencil, commonly referred to as a screen, which allows ink to pass through selectively onto the desired surface. The screen printing material is traditionally made of a finely woven mesh material, such as polyester, nylon, or stainless steel, stretched tightly over a frame. The mesh is coated with a light-sensitive emulsion, which is then exposed to UV light using a film positive of the design. The areas of the screen that are exposed to light harden, while the unexposed areas remain water-soluble.

The mesh serves as the canvas through which ink is transferred onto the substrate. Its composition, thread count, and tension are vital factors that determine the final print quality. Let's explore the role of mesh in creating vibrant and crisp prints:

1.Mesh Composition: Different materials offer varying characteristics and advantages. Polyester mesh is the most commonly used due to its durability, cost-effectiveness, and ability to hold fine details. Nylon mesh is known for its strength and is often preferred for printing on rougher surfaces. Stainless steel mesh, while less common, is highly durable and suitable for specialized applications requiring extreme precision.

2.Thread Count: The thread count refers to the number of threads per inch in the mesh. A higher thread count provides a finer and more detailed print, but it may also restrict the amount of ink passing through. Lower thread counts allow more ink flow but may result in less sharpness. The choice of thread count depends on the level of detail required in the design and the thickness of the ink being used.

3.Mesh Tension: Proper tension is crucial for achieving crisp prints. The mesh must be stretched tightly across the frame to ensure uniform and consistent ink transfer. Insufficient tension can lead to ink bleeding or smudging, while excessive tension may cause the mesh to break or create uneven pressure on the substrate. Maintaining the right tension throughout the printing process is essential for achieving accurate registration and fine detail.

4.Mesh Aperture: The aperture, or opening size, of the mesh affects the ink flow and determines the thickness of the printed deposit. Finer meshes with smaller apertures are suitable for printing fine lines, small text, and intricate details. Coarser meshes with larger apertures are better for bold and solid designs. The ink viscosity and desired effect guide the choice of mesh aperture.

5.Mesh Degradation: Over time, mesh can degrade due to various factors such as exposure to chemicals, abrasion, or excessive tension. Deteriorated mesh can affect print quality by causing inconsistencies, uneven ink distribution, or blurred edges. Regular inspection and maintenance of screens, as well as timely replacement of worn-out mesh, are essential for ensuring consistent and vibrant prints.

In addition to the factors mentioned above, other variables such as ink type, squeegee pressure, and screen-to-substrate distance also influence the final print outcome. Achieving the desired vibrancy and crispness requires a delicate balance between these variables, with the mesh playing a critical role as the medium through which the ink is transferred.

Screen printing frames, with its blend of artistry and technical precision, continues to captivate artists, designers, and printers alike. The choice of mesh, along with the mastery of other printing variables, unlocks the potential for creating stunning and visually striking prints. By understanding the significance of mesh composition, thread count, tension, aperture, and maintenance, screen printers can elevate their craft, unlocking new possibilities and ensuring the creation of vibrant and crisp prints that leave a lasting impression.

Whether it's a T-shirt, a poster, or an artistic masterpiece, the art of screen printing, guided by the capabilities of mesh, breathes life into designs and colors, making them leap off the surface with remarkable clarity and vibrancy.