Screen Printing Mesh Maintenance: Best Practices for Prolonging the Lifespan of Your Mesh

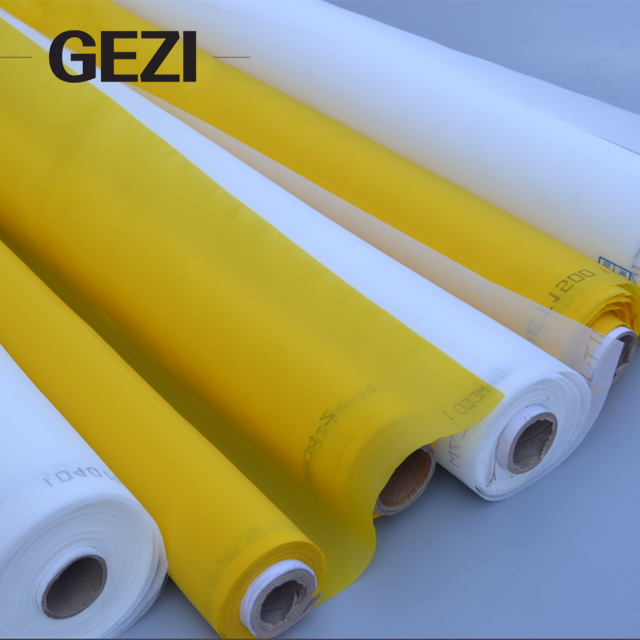

Screen printing mesh is a popular and versatile method of transferring designs onto various substrates. Whether you're printing t-shirts, posters, or other promotional materials, the quality and lifespan of your silk screen printing meshare crucial factors in achieving consistent and desirable results. Proper maintenance of your mesh is essential for extending its lifespan and ensuring the longevity of your printing equipment. In this article, we will explore some best practices for screen printing mesh maintenance that will help you maximize its durability and performance.

Cleanliness is Key: Regular cleaning of your mesh screen printing is vital to prevent ink buildup and clogging, which can cause premature deterioration. After each print run, remove excess ink from the mesh using a gentle brush or a dedicated mesh cleaning tool. Be sure to use a cleaning solution specifically designed for screen printing to avoid damaging the mesh. Proper cleaning not only removes ink residues but also helps maintain the mesh's tension and overall performance.

Handle with Care: Printing screen meshis delicate and can be easily damaged if mishandled. Always handle the mesh with clean hands and avoid applying excessive force or pressure. When removing or installing mesh on the frame, take care not to stretch or distort it. Be mindful of sharp edges or objects that can snag or tear the mesh. By handling the mesh gently, you can minimize the risk of damage and extend its lifespan.

Maintain Proper Tension: Maintaining the correct tension in your screen printing mesh screens is crucial for achieving crisp and accurate prints. Over time, mesh tension can loosen due to repeated use and stretching. Regularly check the tension using a tension meter or a tension measuring device and re-tension the mesh when necessary. This will help ensure consistent and high-quality prints, while also preventing undue stress on the mesh fibers.

Store Mesh Properly: When not in use, store your screen print cloth mesh in a clean and dry environment. Avoid exposure to direct sunlight or extreme temperatures, as these can degrade the mesh over time. Consider using protective covers or bags to shield the mesh from dust, dirt, and potential damage. Proper storage not only safeguards the mesh but also maintains its shape and tension, allowing it to perform optimally when needed.

Regular Inspections: Perform routine inspections of your polyester screen printing mesh to identify any signs of damage or wear. Look for frayed or broken strands, holes, or any noticeable defects. Early detection of such issues allows for timely repairs or replacements, preventing further damage and ensuring consistent printing quality. Additionally, check the mesh attachment to the frame, ensuring it is secure and properly aligned.

Use Mesh Protectors: Consider using mesh protectors or barriers during the printing process to shield the mesh from direct contact with the substrate. This protective layer helps minimize abrasion and extends the life of the mesh. Mesh protectors can be in the form of specialized films, adhesives, or emulsions, depending on your specific printing requirements. They act as a sacrificial layer that absorbs the wear and tear, preserving the integrity of the mesh.

Replace When Necessary: Despite proper maintenance, nylon screen printing mesh has a limited lifespan. Over time, the repeated stress, exposure to inks and chemicals, and wear and tear will take their toll. Recognize the signs of irreversible damage or deterioration, such as excessive breakage, loss of tension, or severe mesh degradation. When the mesh becomes compromised, it's important to replace it promptly to avoid compromising print quality and risking damage to your equipment.

By following these best practices for 420 mesh screen printing maintenance, you can significantly prolong its lifespan and ensure optimal printing performance. Regular cleaning, careful handling, maintaining proper tension, and storing the mesh correctly will help you achieve consistent and high-quality prints, while also protecting your investment in screen printing equipment. Remember, a well-maintained mesh not only saves you time and money but also opens the door to endless creative possibilities in the world of screen printing mesh.