Achieving Precision and Detail: Unveiling the Secrets of High Mesh Count Screen Printing

Title: Achieving Precision and Detail: Unveiling the Secrets of High Mesh Count Screen Printing

Introduction

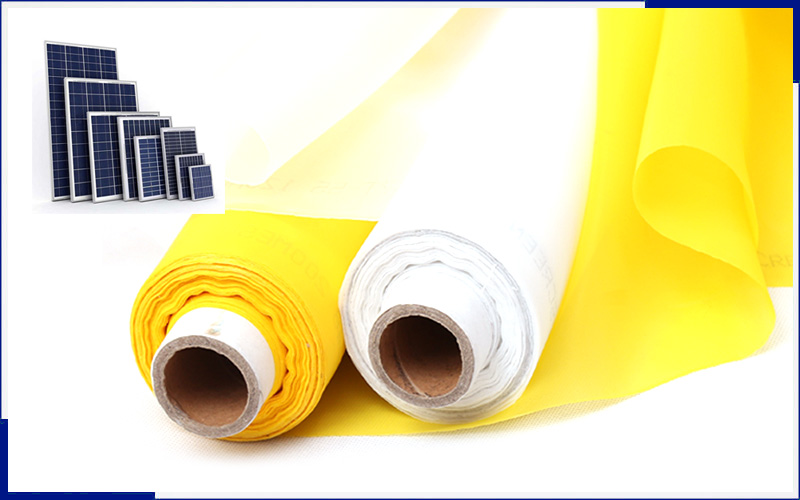

Screen printing mesh has long been a popular method for creating vibrant and detailed prints on various surfaces. One of the key factors that determine the quality and level of detail in screen printing is the mesh count of the screen. Higher mesh count screens enable finer details and sharper prints, making them a preferred choice for intricate designs. In this article, we will delve into the secrets of high mesh count screen printing, exploring the techniques and considerations that contribute to achieving precision and detail in the printing process.

1.Understanding Mesh Count

Mesh count refers to the number of threads per linear inch in a screen. It is represented by a number followed by "mesh" (e.g., 200 mesh). Higher silk screen printing have a greater number of threads per inch, resulting in smaller openings or holes through which the ink passes during printing. This finer mesh structure allows for greater control over ink deposition and is crucial for achieving precise and detailed prints.

2.Selecting the Right Mesh Count

Choosing the appropriate mesh count depends on various factors, including the type of substrate, ink viscosity, and desired level of detail. Generally, higher mesh counts ranging from 200 to 305 are ideal for fine artwork, halftones, and intricate designs. However, it is essential to strike a balance between detail and ink flow. Using a mesh count that is too high might lead to challenges in ink penetration, resulting in incomplete prints or clogged screens. Experimentation and testing on different substrates can help identify the optimal mesh count for a specific project.

3.Mesh Tension and Stretched Frames

To achieve the desired precision and detail in high mesh screen printing, proper tension is critical. Mesh tension refers to the level of stretch or tension applied to the screen fabric when it is attached to the frame. Insufficient tension can result in loose and sagging mesh, leading to blurred or distorted prints. Using a tension meter and following manufacturer recommendations can help maintain consistent and appropriate tension levels, ensuring accurate ink transfer.

4.Screen Preparation and Emulsion

Effective screen preparation is crucial for high printing screen mesh. Prior to coating the screen with emulsion, it is essential to clean and degrease it thoroughly to remove any contaminants that could affect print quality. A properly prepared screen will have a clean, evenly coated emulsion layer, resulting in better ink flow and sharper prints. Additionally, using a higher resolution film positive or an appropriate direct-to-screen exposure system can further enhance the level of detail.

5.Ink Selection and Viscosity

Choosing the right ink and managing its viscosity is vital for achieving precision in high screen printing mesh silk. Water-based and solvent-based inks are commonly used, each with its own characteristics. Water-based inks tend to have lower viscosity and work well for fine details, while solvent-based inks offer excellent opacity and color vibrancy. It is essential to adjust the ink viscosity to ensure smooth ink flow through the fine mesh openings. Proper ink consistency helps prevent ink clogging, smudging, or bleeding, resulting in sharper prints.

6.Printing Techniques and Pressure Control

The printing technique employed also plays a significant role in achieving precision and detail. Consistent pressure control during the printing process is vital to ensure proper ink deposition onto the substrate. Manual or automatic presses equipped with micro-registration systems allow for precise control of print placement, ensuring accurate registration of multiple colors and fine details. Maintaining a consistent squeegee angle and speed helps prevent ink inconsistencies and ensures uniform coverage across the design.

Conclusion

High screen print cloth mesh opens up a world of possibilities for achieving precision and detail in printed artwork. By selecting the right mesh count, maintaining proper tension, preparing screens diligently, choosing the appropriate inks, and employing meticulous printing techniques, screen printers can unlock the potential for creating