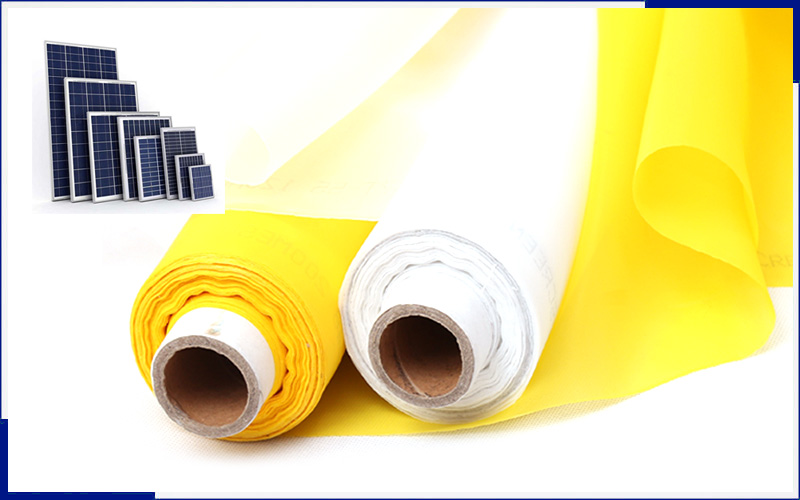

White or yellow silk screen printing mesh

White mesh is the more economical of the two, and is primarily seen in lower mesh counts used for less-detailed designs. Higher count mesh is usually dyed yellow because the color yellow acts as a canceling factor for UV light and prevents refraction along the mesh strands when burning your screen printing fabric. This allows for a more focused and precise exposure, keeping your screens as crisp as possible.

60 Mesh - A Course mesh count for use with Glitter Inks.

86/90 Mesh - Recommended for printing opaque white/light colors onto dark fabric to allow maximum opacity.

110 Mesh - Recommended for general textile work, printing light on dark, dark on light.

125/160 Mesh - Recommended for general textile work but with some finer detail/line work.

180/200 Mesh -Textiles; smooth and light fabric, Half-Tone, General.

230/250 Mesh - Textiles; extremely light material, Graphics, General.

305/355 Mesh - Process work