Which Mesh Count you should be using and some substrates is right for

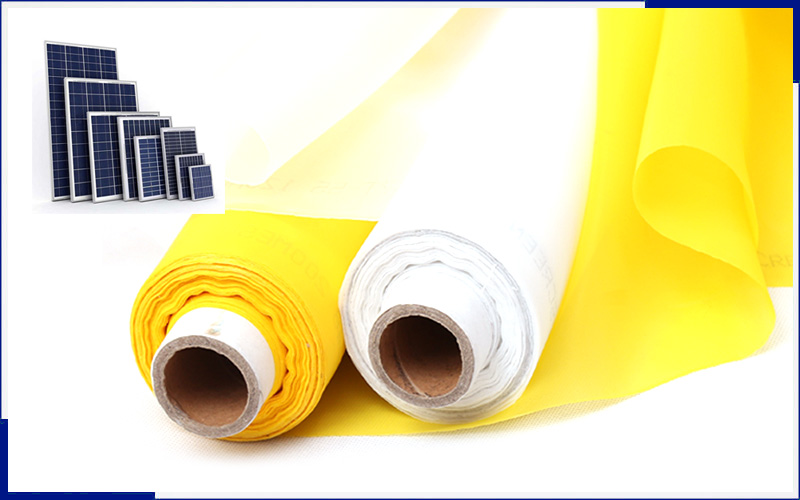

Our screen printing mesh is super high quality, monofilament polyester mesh that's durable and a pleasure to print with.

- 32T (80 US) is what we consider quite a low mesh count. It will lay down heavy deposits of ink on to fabric but doesn't always give the best results on fabric. Can also be used for some specialist inks. (like glitter inks).

- 43T (110 US) This is without doubt the most commonly used mesh, it is ideal for printing text and blockier designs on T Shirts, Hoodys etc as well as other textiles. Its is still perfect for paper prints as long as the design is not to detailed.

43T is ideal for printing underbase layers. It can leave a nice deposit of base layer for you to print your colour on the top. This will leave a nice opaque print. Ideal with Waterbased or plastisol inks.

- 55T (140 US) is great for silk screen printing mesh on T Shirts, Hoodies with a little more detail. A good alternative to 43T mesh if you use one screen for different prints.

- 77T (196 US) is great for finer detail, lightweight textiles such as fine cotton. It is also great for printing on paper, card and other substrates.

- 90T (230 US) Our favourite mesh count for high detail fabric and paper printing. Good for thinner inks on delicate fabrics like silk. An ideal mesh count for halftone prints and CMYK printing. 90T is the perfect top layer mesh count. It leaves a thin but clean layer of ink on your underbase.

- 120T (305 US) is great for finer detail and printing on fine quality paper and card with fine detail. It doesn't let much ink through so its not ideal for bold prints on fabric. 120T is what we recommend for fine lines and text.

Lower mesh counts (and bigger holes in the mesh..) does not always mean more ink and more opaque prints. Often a higher mesh count will give a better result as the ink deposit is more controlled and detail is higher.