The difference between flat screen printing and rotary screen printing

Since most silkscreen printing processes are different, we can discuss the differences between flat and rotary Screen printing mesh processes

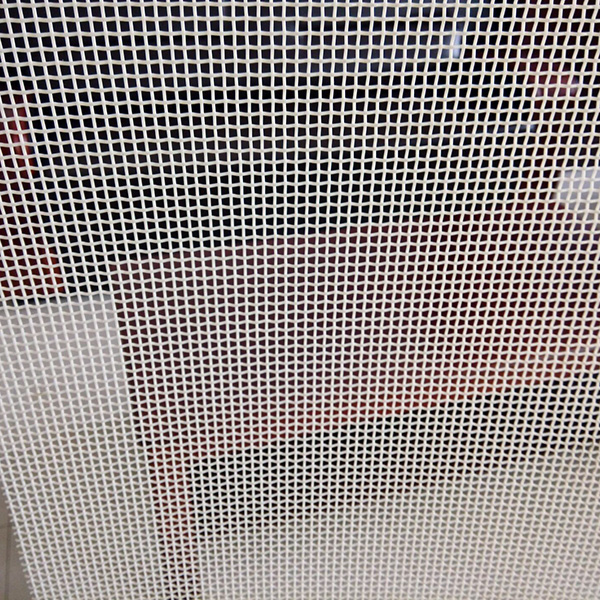

1. In "flat printing screen technology", the printing screen is flat and can be moved up and down. Next to it, the rotating screen is round and rotating.

2. In flat screen printing, extrusion is used. In rotary screen printing, only rollers are used.

3. Small width, cloth (45-50 ") printed on flat screen printing. On the other hand, a large width fabric mesh is printed on the rotary screen printing.

4. Only 6 to 8 colors are available in flat screen printing. However, if you use "rotary screen printing", you will be able to use 16 to 24 colors in the pattern.

5. Flat screen printing process reduces productivity. Moreover, rotary screen printing is faster than flat screen printing, and its productivity is three times of the latter.

6. The initial investment cost of flat screen printing machine is low, so the price is cheap. However, the initial investment cost of rotary screen printing is too high; therefore, it is very expensive.

However, the rotary screen printing press is expensive. In today's era, the textile industry uses expensive products because of their productivity and flexibility.