Polyester Screen Printing Mesh

Basic Information about Polyester Screen Printing Mesh, Weaving, Uses, How to Choose Mesh Counts and Weaving Types of Polyester Mesh for Silk Screen Printing, also Introduction of the Screen Printing Technology

Polyester screen for printing is a Plain Woven mesh bolting cloth made with polyester monofilament yarn. PW, the simplified term of Plain Weaving, is the popular processing for polyester mesh. PW will be marked on most polyester mesh products labels while sometimes TW(twilled weave) will be found for much micron or stronger fabrics. However TW polyester fabric will somewhat delay the ink flow according to certain reports. Polyester mesh printing screen is one of the most advanced high-tech fabric products started in 1990s for screen printing. polyester and nylon screen products can work easily with all types of printing machines.

About Screen Printing:

It is a technique achieved through the screening processing of polyester fabric. Screen printing is a modern printing method popular for making T-shirts and other garments, but also widely used for Textile Printing, Ceramic Printing, Glass Printing, Graphics Printing, Electronic Printing, CD/DVD Printing, Wood printing, Metal printing, Plastic and leather printing.

Characteristics of Silk Screen Printing Mesh:

· optimized mesh geometry

· balanced, low elongation

· strength for larger formats

· modest loss of tension

There are two factors may influence the printing results: One is the weaving type of the print mesh screen, the other is the mesh count.

Weave Types of the Polyester Print Screen Will Effect Printing Result:

The most common weaving pattern in screen printing mesh is called "plain weave" and will be designated on labels as "PW." It is a simple over-and-under weaving pattern. "Twill weave (TW)" is used to create thicker, sturdier screens and relies on complex patterns of weaving, which vary depending on the manufacturer. Twill weave mesh will be thicker than plain weave even if the mesh count is identical. The Screen Printing Technical Foundation compared the different weave's performance and found that twill weave transferred somewhat less ink than plain weave.

Common Mesh count applied for the printing screen: DPP8T - DPP180T

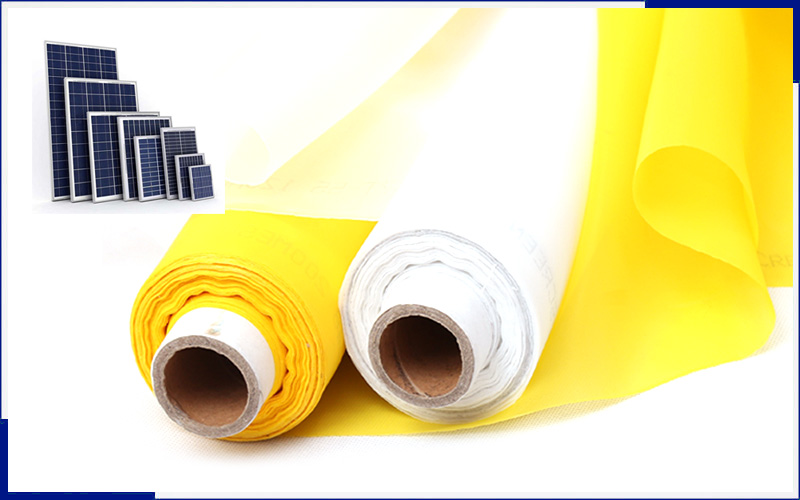

Color : Yellow & White

Fabric Width : 110cm - 365cm

How to Choose Mesh Count for Your Polyester Printing Screen (Bolting Cloth) and Its Influence on Silk Screen Printing Mesh Fabric:

A selection of mesh is typically organized by "mesh count," or the number of threads per square inch, such as 110, 180 and 240. The lower the number is, the larger the openings are that the ink will be pressed through onto your fabric; a higher number means more threads per inch and smaller openings that allow less ink to transfer. If the stencil has a lot of detail and small or narrow portions of the mesh are covered, then a high mesh count screen is appropriate. Larger openings will let in too much ink and potentially muddle the edges and details of the image.

Common silk screen printing sizes:

Low elongation and high tensile strength

Material100%polyester monofilament

Mesh count: 25 mesh, 420 mesh

Width: 115cm[45"inch] and 165cm[65"inch]

Color: White and Yellow

Mesh size: 15mesh/inch, 25mesh/inch, 30mesh/inch, 38mesh/inch, 60mesh/inch, 75mesh/inch, 80mesh/inch 100mesh/inch, 110mesh/inch, 120mesh/inch, 135mesh/inch, 160mesh/inch, 180mesh/inch.