Choosing the Right Nylon Flour Mesh A Guide to Mesh Types and Their Uses

Understanding Nylon Flour Meshes

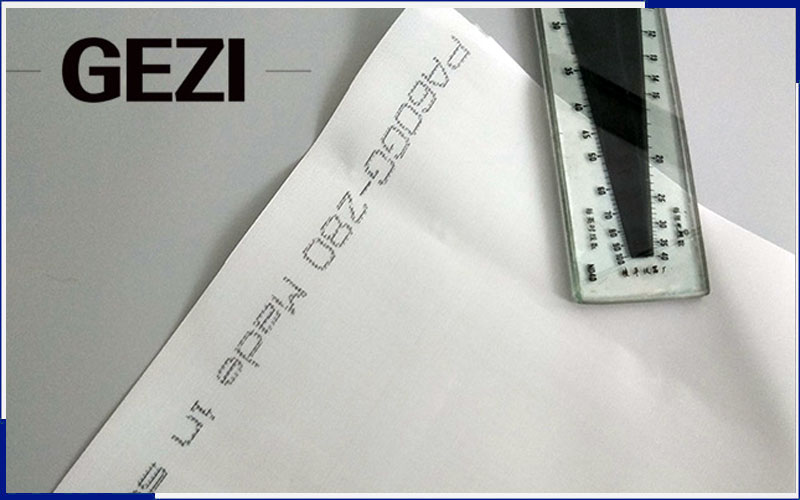

Nylon flour meshes are made from fine, durable nylon threads that are woven together to create a mesh structure. These meshes come in various sizes, referred to as mesh counts, which indicate the number of threads per inch. The higher the mesh count, the finer the mesh and the smaller the particle size it can sift. Mesh counts typically range from 20 to 200 or more.

Different Mesh Types and Their Uses

1. Coarse Mesh (20-40 mesh)

Coarse nylon meshes with lower mesh counts are ideal for sifting large particles, such as whole grains or flours with larger particles. These meshes are commonly used in initial sifting processes to remove larger impurities and ensure a smoother starting material for further refinement.

Uses: Whole grain flours, initial sifting of coarse flours, removal of larger impurities.

2. Medium Mesh (50-80 mesh)

Medium nylon meshes strike a balance between coarseness and fineness, making them versatile for a variety of applications. These meshes are suitable for sifting all-purpose flours and can help break down any clumps or lumps that may have formed.

Uses: All-purpose flours, breaking down clumps, achieving smoother textures.

3. Fine Mesh (100-120 mesh)

Fine nylon meshes are designed for precision sifting and are commonly used in delicate baking and pastry recipes. These meshes excel at removing smaller particles and creating finer flour textures, resulting in lighter and fluffier end products.

Uses: Cake flours, pastry flours, achieving fine textures in delicate recipes.

4. Extra Fine Mesh (150-200 mesh)

Extra fine nylon meshes are the pinnacle of precision sifting. They are ideal for achieving the finest flour textures necessary for specialized culinary applications. These meshes are often used in professional bakeries and patisseries where impeccable texture is paramount.

Uses: High-end pastries, professional baking, specialty flour refinement.

Factors to Consider When Choosing a Nylon Sieve

Recipe Requirements: Consider the type of recipes you frequently prepare. If you often work with delicate pastries, a fine or extra fine mesh might be more suitable. For heartier bread recipes, a medium mesh could suffice.

Texture Preference: Think about the desired texture of your end product. If you're aiming for a lighter texture, you might opt for a finer mesh to achieve smoother and fluffier results.

Versatility: If you want a mesh that can handle a variety of tasks, choosing a medium mesh could be a versatile option that covers most of your sifting needs.

Culinary Expertise: Professional bakers and chefs might opt for extra fine meshes to meet the highest standards of refinement, while home cooks might find that medium or fine meshes meet their requirements.

Budget: The finer the mesh, the more intricate the weaving process, which can influence the cost. Consider your budget and how frequently you'll use the mesh before making a decision.

Maintenance and Care

To ensure the longevity and effectiveness of your nylon mesh sieve, it's essential to maintain and care for it properly. After each use, tap the mesh gently to remove excess flour particles and then rinse it under running water. Avoid using harsh chemicals or abrasive scrubbers, as these can damage the delicate nylon threads. Allow the mesh to air dry thoroughly before storing it in a cool, dry place.

Conclusion

Choosing the right flour sieve mesh is an important decision that can impact the quality of your culinary creations. By understanding the different mesh types and their uses, you can make an informed choice that suits your recipes and preferences. Whether you're baking delicate pastries or hearty breads, selecting the appropriate mesh count will contribute to achieving the desired texture and consistency in your flour-based products.