A Closer Look at Nylon Flour Mesh From Production to Practical Uses

Understanding Nylon Flour Mesh Production

Nylon flour mesh, also known as a sieve or a mesh strainer, is primarily used for sifting flour or other dry ingredients. The production of nylon flour mesh involves several intricate steps that ensure its durability, mesh consistency, and ability to effectively separate fine particles from larger ones.

Material Selection: Nylon polymers are the base material for manufacturing nylon flour mesh. Nylon is chosen for its strength, flexibility, and resistance to abrasion and chemicals. The selection of the right type of nylon is crucial, as it impacts the mesh's performance under various conditions.

Extrusion: The production process starts with extruding nylon polymers into thin strands. These strands are then woven together to form a mesh-like structure. The spacing between the strands determines the mesh's fineness and is measured in mesh count (the number of strands per inch).

Weaving: The woven nylon strands are interlaced using advanced weaving techniques. The weaving process ensures uniform spacing between the strands, which directly affects the mesh's sieving accuracy. High-quality weaving is necessary to prevent inconsistencies and irregularities in the mesh.

Heat Setting: After weaving, the mesh is heat-set to stabilize its structure. This process involves subjecting the mesh to controlled heat, which helps the nylon fibers retain their shape and prevents them from stretching or deforming during use.

Calendering: Calendering is the process of passing the mesh through rollers to flatten and smooth the surface. This step is important to achieve consistent mesh thickness and to remove any irregularities that might affect sieving performance.

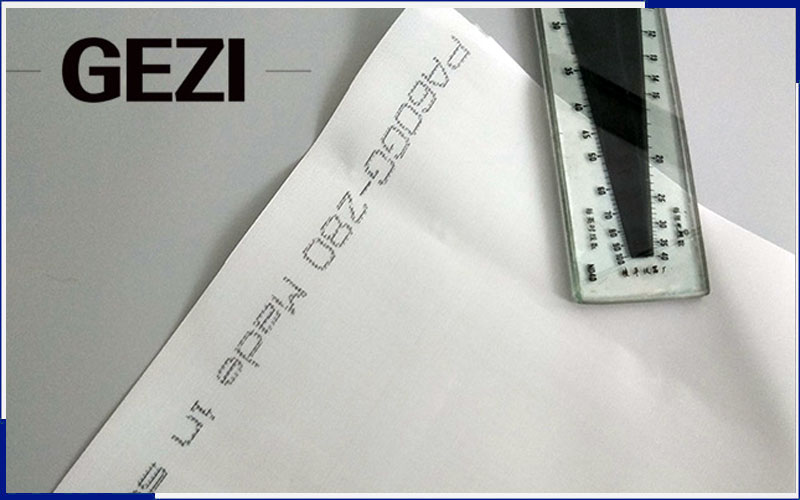

Quality Control: Throughout the production process, rigorous quality control checks are conducted to identify and rectify any defects. Mesh integrity, uniformity, and mesh count are among the key parameters assessed during quality control.

Practical Uses of Nylon Flour Mesh

The culinary world relies on nylon flour mesh for a multitude of purposes that extend beyond basic sifting. Here are some practical uses of nylon flour mesh in the food industry:

Sifting Dry Ingredients: The primary purpose of nylon flour mesh is to sift dry ingredients like flour, cocoa powder, and powdered sugar. By breaking down clumps and aerating the ingredients, the mesh ensures even distribution and smooth incorporation into recipes, leading to consistent results in baking and cooking.

Straining Liquids: Nylon sieve's versatility also extends to liquid applications. Chefs and bakers use finer mesh sizes to strain liquids, removing impurities, seeds, or larger particles from sauces, stocks, and beverages.

Dusting and Decorating: Pastry chefs and bakers often use nylon flour mesh to evenly dust powdered sugar or cocoa powder over desserts, creating a polished finish. Additionally, mesh patterns can be used to create decorative patterns on cakes and pastries by sprinkling colored powders.

Blanching and Blanching Vegetables: Coarser nylon flour mesh is employed in blanching vegetables – a process that involves quickly boiling vegetables and then cooling them rapidly. The mesh helps immerse the vegetables in boiling water and transfer them to an ice bath efficiently, preserving their color and texture.

Cheese and Dairy Processing: In cheese production, nylon mesh sieve is used to drain whey from curds during the cheese-making process. It's also employed in making dairy products like yogurt, where it aids in straining and thickening.

Tea and Infusion: Nylon mesh with larger openings is suitable for holding loose tea leaves or herbs, allowing for easy brewing of teas, herbal infusions, or flavoring stocks.

Conclusion

Though often overlooked, flour nylon mesh plays a pivotal role in the food industry, contributing to the precision, consistency, and quality of various culinary creations. From its intricate production process to its wide range of practical uses, this unassuming tool has earned its place as an essential component in the art of food processing and preparation. As chefs, bakers, and food manufacturers continue to seek excellence, the nylon flour mesh remains a steadfast companion in their journey to culinary perfection.